One Dragon

The entire process - cultivation, processing and marketing is solely done by the Company under strict quality control.

DXN was founded by Datuk Lim Siow Jin, a graduate from the prestigious Indian Institute of Technology. Datuk Lim started the business in quest of the benefits of mushroom on human health. His deep interest and endless effort drove him to utilize the fullest potential of Ganoderma or Lingzhi, which is well-known as the King of Herbs, for human health and wealth, with the establishment of DXN in 1993.

The core business activities of DXN include cultivation, manufacturing and marketing of the health food supplements. Based in Malaysia with worldwide operations, the company is well-known for its Ganoderma business. Its product lines include dietary supplements, food and beverages, personal care products, skin care and cosmetics, household products and water treatment system. Since its inception in 1993, DXN has upheld its concept of 'One Dragon One World One Market and One Mind'. With this powerful concept, DXN has sailed through continuous growth over the years. On 30 September 2003, DXN Holdings Berhad was listed on the Main Board of Bursa Malaysia. DXN was delisted on 27 December 2011 due to a take-over offer by the founder.

DXN Holdings Berhad is the investment holdings and management company of DXN Group. DXN's high regard for quality earned the company many outstanding citations and recognitions from various health and business organizations. Along with the solid foundation and sustainable development, DXN has rapidly diversified into other business activities, which include property, information technology, etc. In its core business of direct selling, the rapid global expansion of DXN is recognized internationally by its vast growth of distributors worldwide and its amplification of footprint in key strategic locations. With over 20 million registered distributors worldwide, DXN is solidifying its position as one of the world leader in Ganoderma products.

Datuk Lim Siow Jin

The entire process - cultivation, processing and marketing is solely done by the Company under strict quality control.

Each and every distributor enjoys worldwide bonus with single membership.

The company and the distributors single-mindedly concentrate on doing DXN business.

Our philosophy - to provide low price and high quality products, to keep a low profile while generating high income is ideal for direct selling. This system is equitably accessible to anyone of any background. Our free enterprise system enables anyone to enjoy personal achievements that lead to greater financial independence. More importantly, numerous people have testified to the benefits of our products when they gained better health through consumption of our products. Our philosophy is the foundation on which our success in the direct selling industry is built.

DXN Logo

RED

RED represents fire to symbolize the company's fighting spirit to progress.

The Red Oval symbolizes the rising sun to represent aggressiveness, single-mindedness and persistence in achieving DXN's vision.

GREEN

GREEN represents trees to symbolize the dynamic growth and expansion of our market.

The Green Branches symbolizes Ganoderma to represent the company's strong commitment for growth and relentless striving to achieve excellence by focusing on the health-based industry.

BLUE

BLUE represents water to symbolize the company as the foundation for all the vigorous developments.

The Blue Horizontal Line symbolizes the company as the power source for the impetus of business development.

Liver Gano

Liver Gano  Heart Gano

Heart Gano  Kimshen Gano

Kimshen Gano  Brain Gano

Brain Gano  Peacock Gano

Peacock Gano  Ruyi Gano

Ruyi Gano  Growing of Mycelium (1 Week)

Growing of Mycelium (1 Week) Growing of deer horn ganoderma (1 Month)

Growing of deer horn ganoderma (1 Month) Intermediate growing stage (2 Months)

Intermediate growing stage (2 Months)  Matured stage (3 Months)

Matured stage (3 Months)  Materials that are used as organic media.

Materials that are used as organic media.  Fill up the polybags with the organic materials. Then, the polybags are closed with plastic caps.

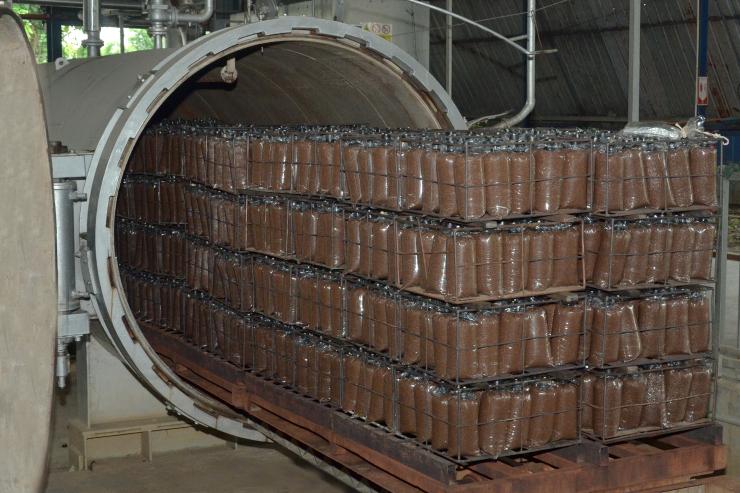

Fill up the polybags with the organic materials. Then, the polybags are closed with plastic caps.  Polybags are placed in the sterilization machines to be sterilized.

Polybags are placed in the sterilization machines to be sterilized.  High technology sterilization machine.

High technology sterilization machine.  The suspension arrangement of polybags is to avoid the pervasion of unwanted materials.

The suspension arrangement of polybags is to avoid the pervasion of unwanted materials.  Harvesting of fresh and nutritious Ganoderma.

Harvesting of fresh and nutritious Ganoderma. Producing capsule through automatic machine.

Producing capsule through automatic machine.  Capsule polishing process to ensure its cleanliness.

Capsule polishing process to ensure its cleanliness.  Insert capsule into the bottles.

Insert capsule into the bottles.  The caps of the bottles are sealed.

The caps of the bottles are sealed.  Bottle labelling to provide a unique identity to ensure product controlling.

Bottle labelling to provide a unique identity to ensure product controlling.  Labelling of manufacturing and expiry date on every product.

Labelling of manufacturing and expiry date on every product.  Finished product ready to be distributed.

Finished product ready to be distributed.